Station:

- A 400MW single-shaft combined-cycle plant, including a 150MW three-pressure HRSG with reheat

Problem:

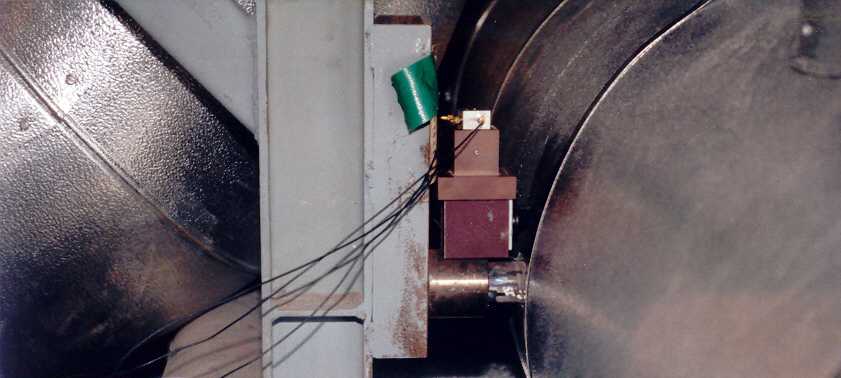

- Irregular movement of a reheater header at maximum load, with potential for reduced fatigue life of tube-to-header welds

Approach:

- Team approach with the prime contractor, OEM and operator

- Design review; plant instrumentation and monitoring

- External observation during operation; internal inspection off-load

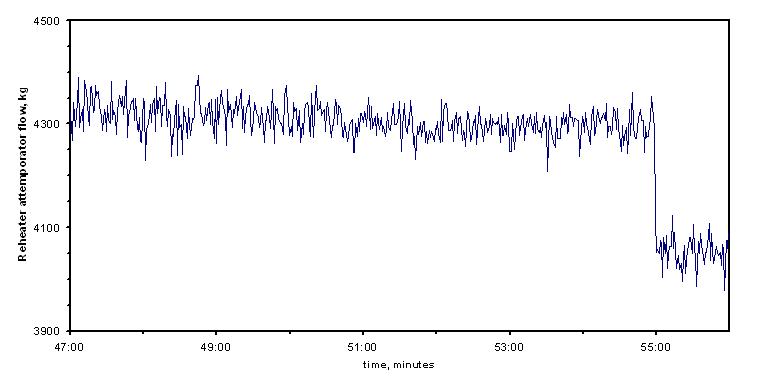

- Investigation of the effect of operational parameters

Benefits:

- Flow induced vibration of tube-bank identified as prime cause, being predicted to generate displacements and frequencies comparable to those observed

- Addition of tube spacers implemented, leading to elimination of problem and allowing operation at full power to be resumed

- Secondary effect of attemporator performance identified as requiring further investigation

Publication:

Brear, J.M. and Jarvis, P.

“Tracing a vibration problem back to source”

ETD Int Conf ‘Heat Recovery Steam Generator Technology’, Woburn House, London, 10-12 Nov 2003