Inspection of critical welds in the cooling pipework on the fuelling machine of an Advanced Gas-cooled Reactor identified high hardness levels in certain cases. This raised questions regarding the heat treatment, and the possibility of inadequate toughness. Further investigation revealed elbows with silicon levels above the specification limit. It therefore became necessary to demonstrate the integrity of the pipework so as to satisfy the insurers that the equipment could return to service, and thus allow the unit to come back on-line at a time of critical power demand.

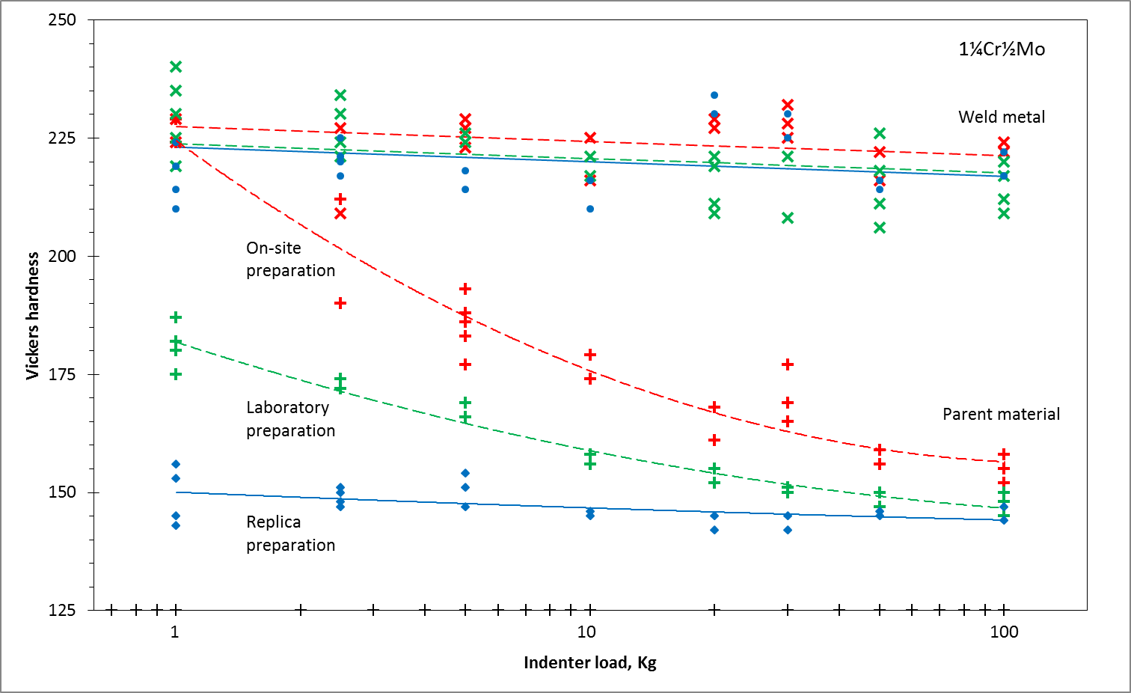

Investigation involved fabrication and testing of procedure welds with and without the specified heat treatment, investigation of on-site hardness measurement techniques, checks of materials chemistry, and replica examination of selected components and welds. Adequate toughness was demonstrated on test welds without heat treatment and the apparent high hardness was shown to be a result of the on-site measurement technique used. Inspection revealed that the straights, elbows and welds had normal microstructures. Analysis showed the detailed chemistry, including the high silicon levels, to be consistent with manufacture to ASME, rather than the intended BS, materials standards – and therefore acceptable after retrospective design change. Costly replacement was thus avoided and the unit returned to service without extended outage time.

1¼Cr½Mo steel, welded and stress-relieved