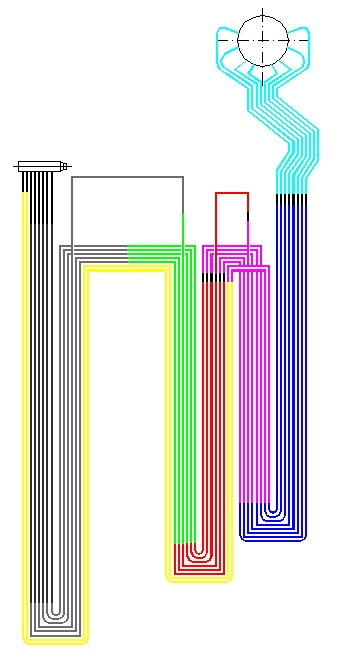

Component:

- Final superheater and reheater tube banks, fabricated from T22 material, in a coal-fired boiler

Problem:

- Design life exceeded; accurate life prediction needed

- Consistent life assessment route required for future use

Approach:

- Probabilistic life assessment, allowing for the interactions between creep, fireside corrosion and steamside oxidation, based on historical operating conditions and inspection data

- Refined assessment using post-exposure rupture test data

Results:

- Assessment based on standard materials data showed an adequate remaining life for the reheater tubes, but indicated that the superheater tubes were potentially in the failure regime already.

- Superheater tube life shown to be creep dominated; reheater tube life shown to be controlled by steamside oxidation.

- Predicted lives refined by use of iso-stress post-exposure tests. Superheater tube material demonstrated to be somewhat above mean properties, and therefore sufficient remaining life could be demonstrated. Reheater tube material shown to be slightly below mean properties, but life still adequate.

- An internal magnetite scale thickness of 2mm predicted for the reheater tubes at end of life, indicating a need for cleaning and suggesting a materials upgrade on replacement.

Benefits:

- Adequate future life demonstrated for both tube banks

- Life-controlling mechanisms confirmed

- Need to address internal scale build-up in the reheater identified

- Consistent life assessment route established