Component:

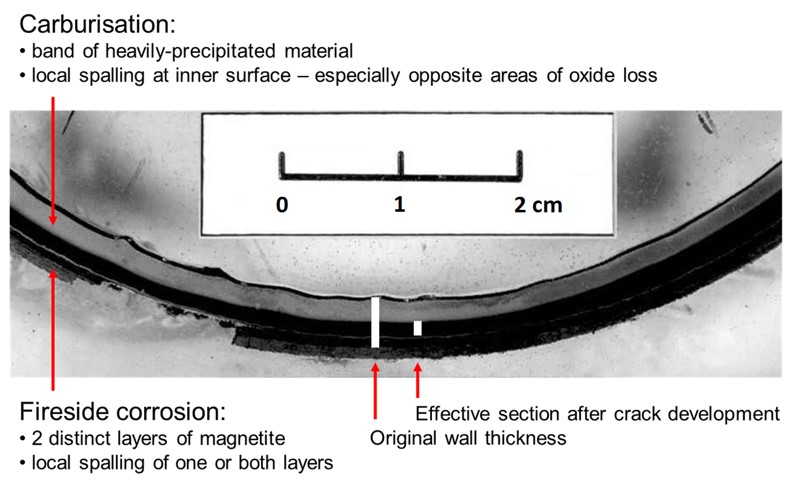

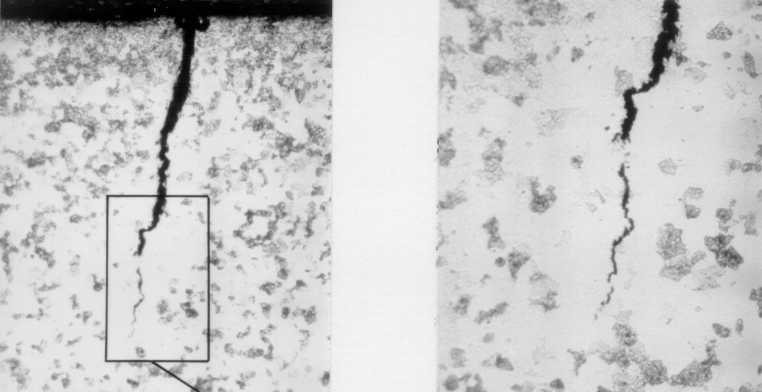

- 9CrMo tubes in a Platformer heater, with severe internal carburisation that had led to cracking and spalling of the carburised layer

Objective:

- to determine the effects of carburisation on tube integrity and life

- to predict the safe remaining life of the tubes

Approach:

- post-exposure rupture testing of tubes having a range of carburisation depths, including comparative tests on samples with the carburised material removed

- probabilistic life assessment, following our standard method.

Results:

- Effect of through-wall carburisation on post-exposure test life determined, for three typical tube materials

- In the early stages of service life this strengthening effect dominates. Later, the accompanying loss of ductility leads to cracking of the carburised layer and a reduction in life.

Benefits:

- Quantified model of the strengthening and weakening effects of carburisation

- Database of in-service carburisation rates

- Database of mechanical properties of carburised tube materials

- A validated, improved method of heater tube life prediction

Publication:

Brear, J.M. and Williamson, J.

“Integrity and life assessment of catalytic reformer units”

Chapter 2 of EFC Publication 42 ‘Corrosion in Refineries’, eds Harston, J.D., Ropital, F.

Inst Materials, Minerals and Mining, London, July 2007, pp 18-46

Franks, A.R., Bagnall, S.L., Brear, J.M., Williamson, J., Conlin, P. Reid, G.

“Carburization and Metal Dusting in Fired Heaters and Steam Methane Reformers:

Plant Integrity Issues”

NACE – AWS Conf. ‘Materials Performance and Welding Technologies’

Dammam, Kingdom of Saudi Arabia, 11-14 September 2017