We provide a proprietary life prediction and management method for:

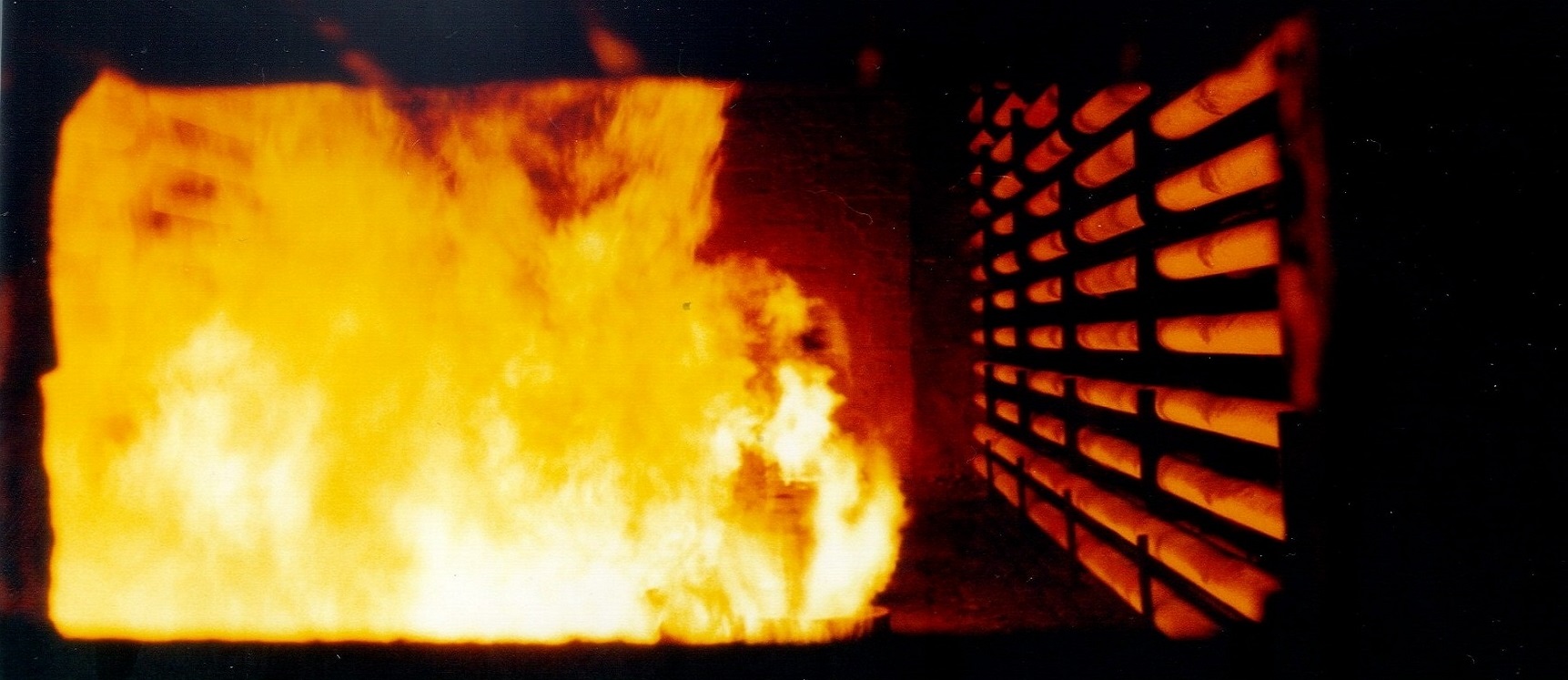

- Fired heaters in refining or process service, operating in or below the creep range, subject to fireside corrosion and internal carburisation, oxidation, or sulphidation.

- Boiler tubes in power generation or steam raising service, operating in or below the creep range, subject to fireside and steamside corrosion and erosion.

The method provides predictions of tube life and condition that are verifiable against inspection findings. This allows intelligent interpretation of condition data, improved planning of tube inspection and management of replacements.

Application is cost effective, timely, flexible and adapted to the client’s specific needs.

A phased assessment approach is employed which is compatible with established risk, reliability and remaining life philosophies. It makes maximum use of all available information, but is not limited by data deficiencies. The scope is regularly extended to accommodate advances in NDE.

The calculations can be progressively refined and updated as information is acquired, thus allowing useful assessment before, during and after inspection outages.

Flexible input options allow calculations to be based on design, nominal or historic data. Materials properties can be taken from standards or from post-exposure testing.

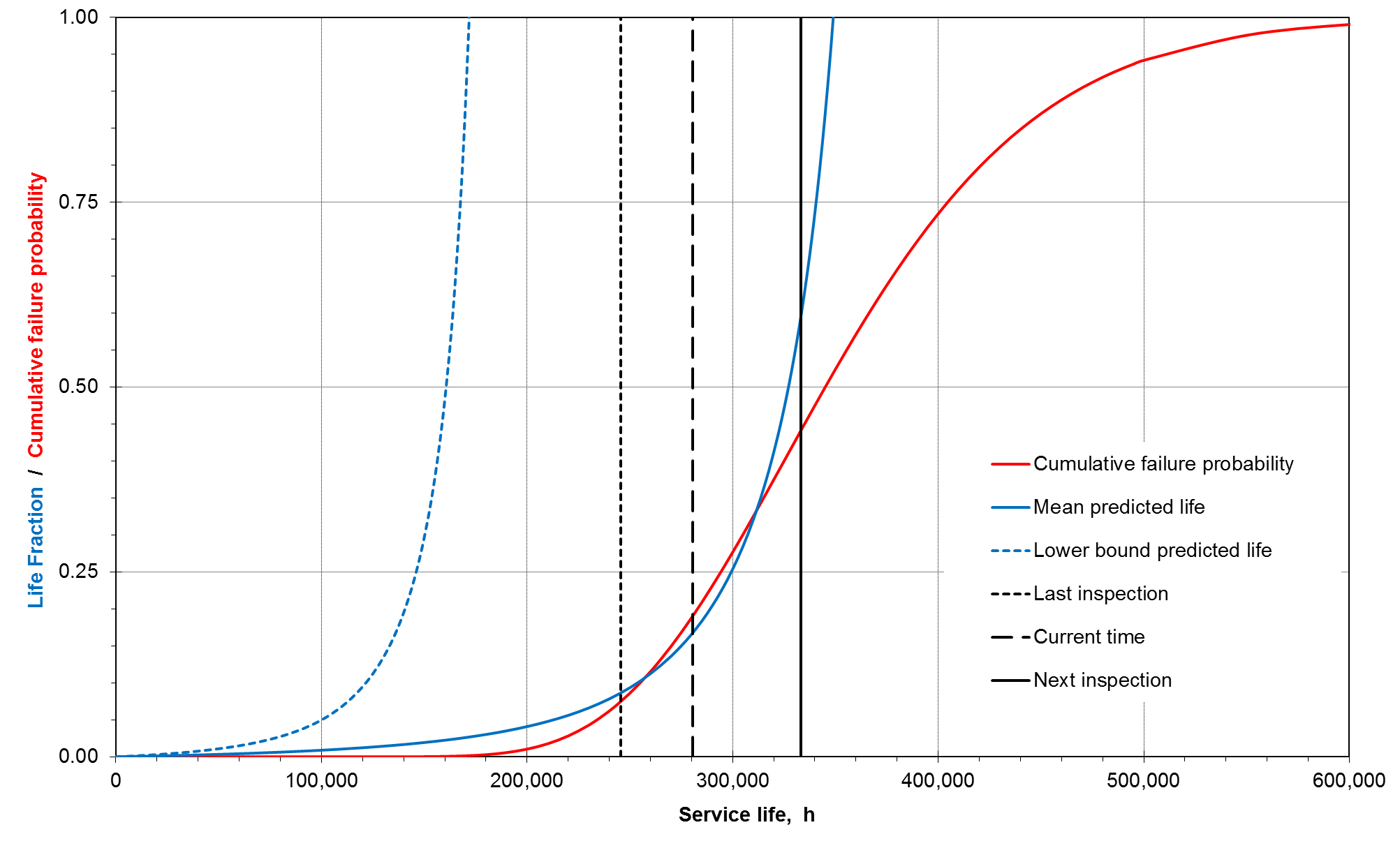

Deterministic and probabilistic options support each assessment stage from preliminary plant ranking through to detailed analysis of critical items. The results may be input to established risk and reliability management tools, allowing cost-benefit analysis of inspection strategies and tube replacement options. ‘What if?’ scenario modelling enables the balance between unit performance and tube life to be optimised.

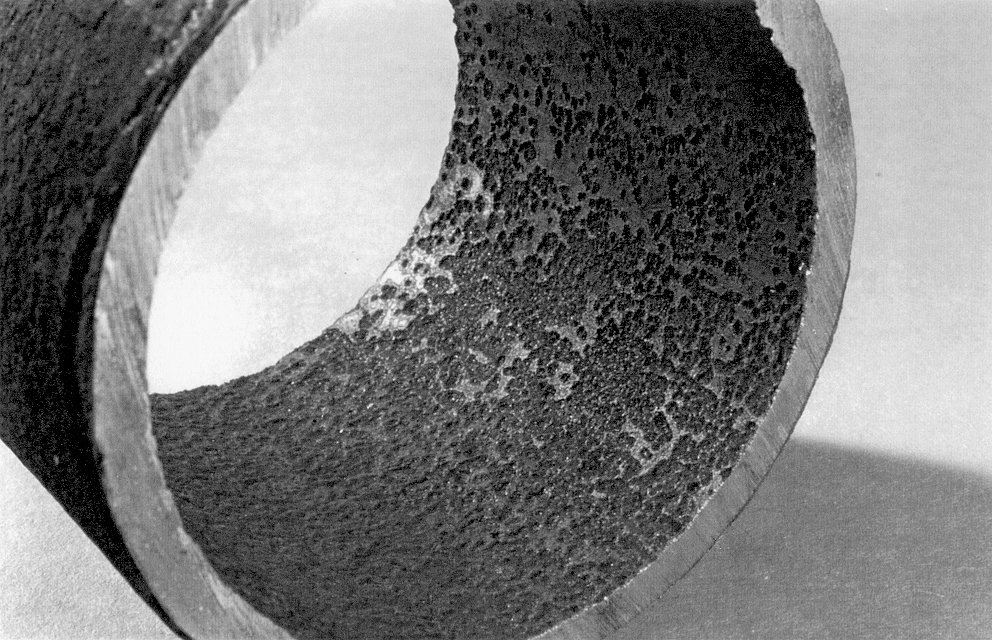

Predictions of condition evolution through to end of life – metal loss, oxide thickness, carburisation depth, diametral strain – are verifiable against progressive inspection data. This increases confidence in the overall prediction and gives early warning of any unforeseen issues.