Final superheater outlet header in a European coal-fired unit, fabricated from P22 and operating at 540°C, 15MPa

Objectives:

- To determine the remaining life of this component

- To demonstrate a consistent life assessment route, that might be applied company-wide to plant built to different design codes

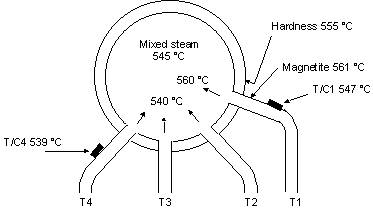

- To compare various temperature measurement and estimation methods

Approach:

Following the phased-approach:

- Phase 1: - Initial code-based calculations

- Phase 2: - Visual inspection, conventional NDE and metallographic examination

- Phase 3: - Installation of conventional thermocouples and off-line diffusion-couple sensors, application of hardness and oxide-thickness based temperature estimation method. Recalculation of header life using quantitative inspection results

Results:

- Header shown to be life-expired according to inverse-design calculations

- Comparison of various code formulae and materials standards showed no significant variation in calculated stresses and lives

- Adequate life demonstrated on the basis of initial inspection results

- Apparent differences between temperature measurements reconciled through realisation that a temperature imbalance existed between the tube rows

Benefits:

- Consistent life assessment route established

- Adequate header life demonstrated for continued operation

- Thermal imbalance identified, leading to loss of unit efficiency and increased stresses in the header

- Potential design modifications proposed to reduce this problem

- Refined FE-based life assessment proposed to address effect of the additional thermal stresses

Published:

Jarvis, P., Jones, G.T., Batista, A. and Araujo, C.L.de,

"Life assessment using codes and standard material properties in SP249 Carregado case study"

SPRINT/KBS Dissemination Workshops of MPA Seminar, Stuttgart, Germany, 6-7th October 1994