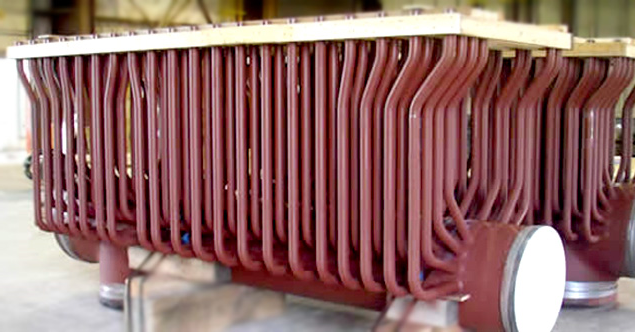

Component:

Shared HP/IP economiser header, fabricated from A106-C

Objective:

Determine likelihood of fatigue cracking at the pressure plate and tube-to-header welds, due to thermal stresses on start-up and during steady operation

Approach:

- Inverse design analysis

- Finite element analysis

- Fatigue life assessment

Benefits:

- Conservative fatigue lives based on standard materials data for initiation and inverse design procedures did not give adequate confidence for future operation

- Fatigue lives based on TRD materials data for initiation, accepted crack growth data and stresses calculated by finite element methods from monitored transient and steady-state temperatures and pressures did give confidence in future operation

- Design changes, although expensive, were identified and implemented