Component:

- A Platformer reactor with creep damage in the main nozzle welds

Objective:

- To ensure an uninterrupted 3-year operating campaign whilst the sister vessel is subject to a major re-engineering exercise

Approach:

- Creep and creep crack growth assessment, following recognised codes and utilising NDE and metallographic inspection results

- Assessment of repair options based on the inspection findings and calculation results

Outcome:

- Experience shows that the life of nozzle welds is strongly dependent on design detail and operating temperature

- For the subject vessel, creep crack growth analysis indicated a strong possibility of cracks growing to a critical size within the required three year period

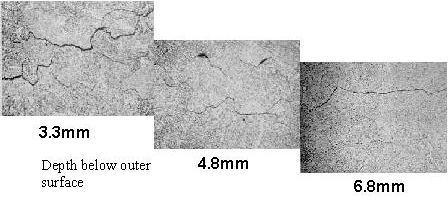

- A damage-depth profile was obtained by taking replicas after grinding the weld to specified depths

- Using this profile a weld repair procedure was developed. This involved grinding to a depth that was predicted to be damage free, confirming the condition by further replication, then re-welding

Benefits:

- The required production regime was achieved

Publication:

Brear, J.M. and Williamson, J.

“Integrity and life assessment of catalytic reformer units”

Chapter 2 of EFC Publication 42 ‘Corrosion in Refineries’, eds Harston, J.D., Ropital, F.

Inst Materials, Minerals and Mining, London, July 2007, pp 18-46