Plant:

- A refinery in the far-east, dating from the 1940s

- Many significant changes through its life

- Currently operating at 115% of design capacity

- Major components have 50,000 - 250,000h service

Objective:

- To provide a Phase 1 combined remaining life study and risk based inspection and maintenance plan

- To provide a basis for life extension

Scope:

- Six units, in the hydroskimming and hydrocracking complexes and the services sector

Approach:

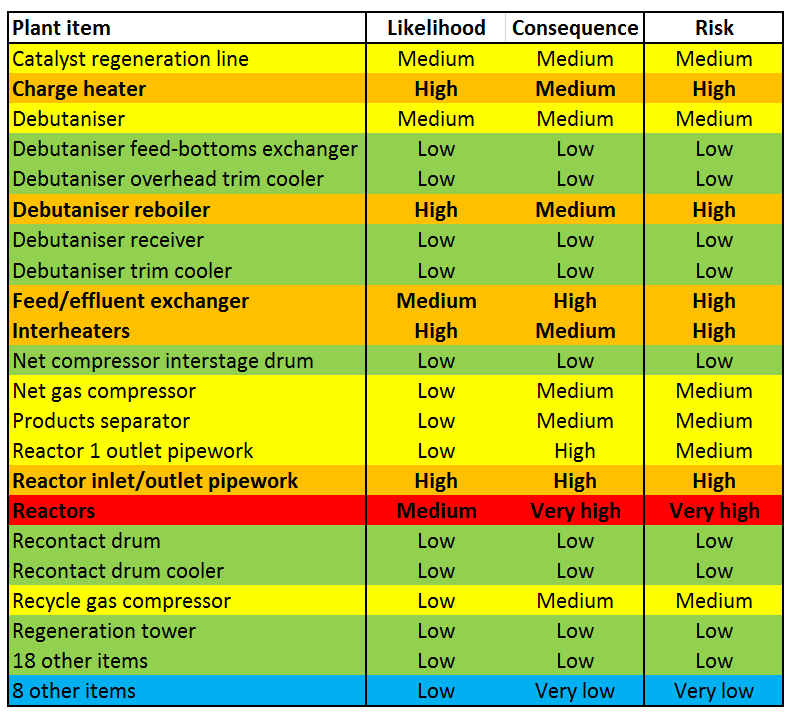

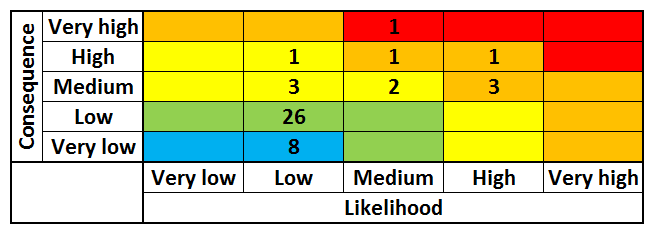

- A check-list Level-1 RBI method, based on an early draft of API 581, simplified to suit the client's budget

- Reliance on the experience of the assessment team

- Phase 1 life assessment, based on design and historical data, for all high risk component types

Results:

- Components categorised into 5 risk levels

- Only the CRU reactors identified as very-high risk in the Level 1 RBI - reduced on the basis of HTHA study, creep life calculations and defect assessment.

- Typically 5-8 high risk component types identified in each unit

Benefits:

- Qualitative prioritisation of component types according to risk level

- Life management plan developed for all high risk component types

- Inspection plan developed for all component types, covering scope, frequency, type of inspection and estimated budget

Published:

Brear, J.M. and Williamson, J,

“Managing the life of high temperature refinery plant - the interaction between risk based inspection and remaining life assessment”

ERA Conf ‘Engineering Asset Management for Utilities, Industry and Commerce’, London, October 1998. Paper 7.4