- Three 250MW systems generating power and process steam for a European aluminium production plant

Problem:

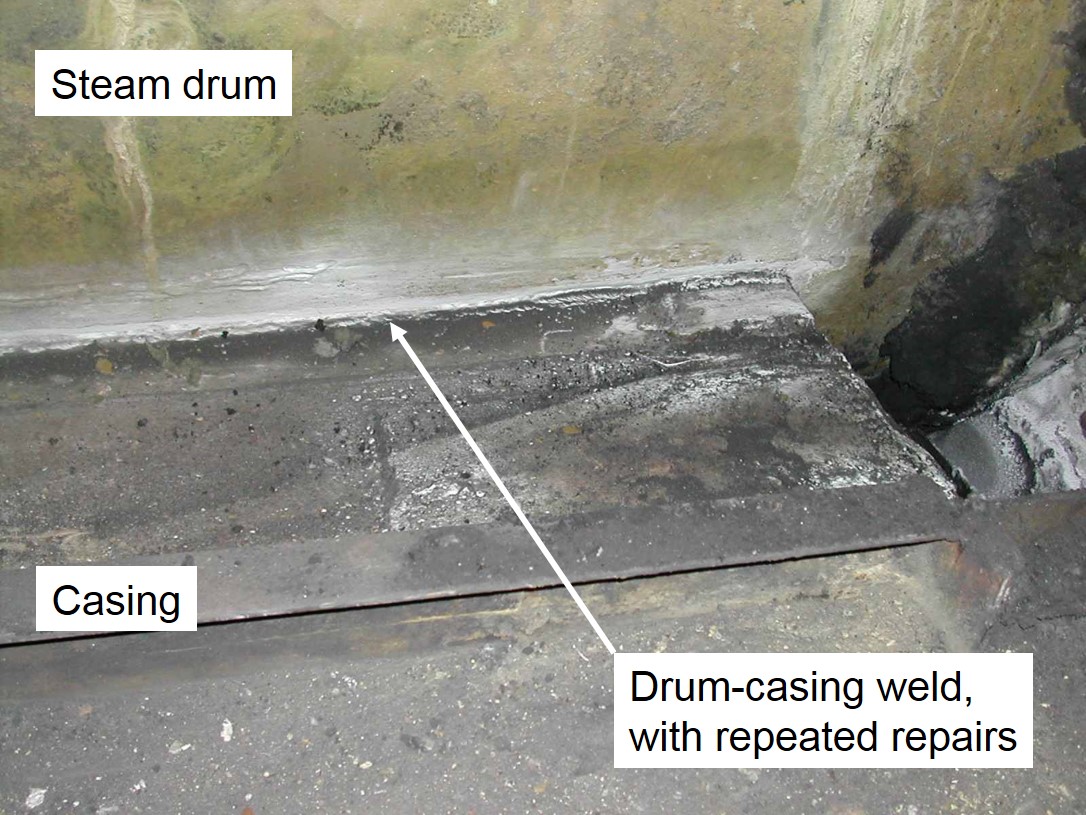

- Severe cracking at welds between the boiler casing and the integral steam drum, leading to loss of exhaust gas with subsequent environmental problems and high maintenance costs

Approach:

- Design review and root cause analysis

- Transient and steady state thermal stress calculations

- Re-design study, including heat conduction calculations to define the type and thickness of insulation required on both the inside and outside of the boiler

Benefits:

- Root cause identified as severe temperature difference between steam drum and boiler casing during normal steady state operation.

- Start up and shut down transients confirmed not to be the cause of the temperature differentials

- An insulation blanket, attached to the inside of the boiler casing to eliminate the severe temperature differentials, designed and fitted

- Environmental issues eliminated

- High cost of regular strip-downs and re-welding eliminated

- Small increase in efficiency and available process steam