Component:

- Waterwall (evaporator) tubes and bends in two designs of boiler at a European power utility

Problem:

- Multiple failures of waterwall tubing, at straights and bends

- In one case, explosive ejection of tube fragments and a large steam release outside the boiler casing

- Significant downtime at a critical production period

Issues:

- History of corrosion failures in the waterwall tubes and bends

- Safety issues with regard to explosive ejection of tube fragments and large steam releases

- Inspection reveals large number of defects remaining in the waterwall tubes

Objective:

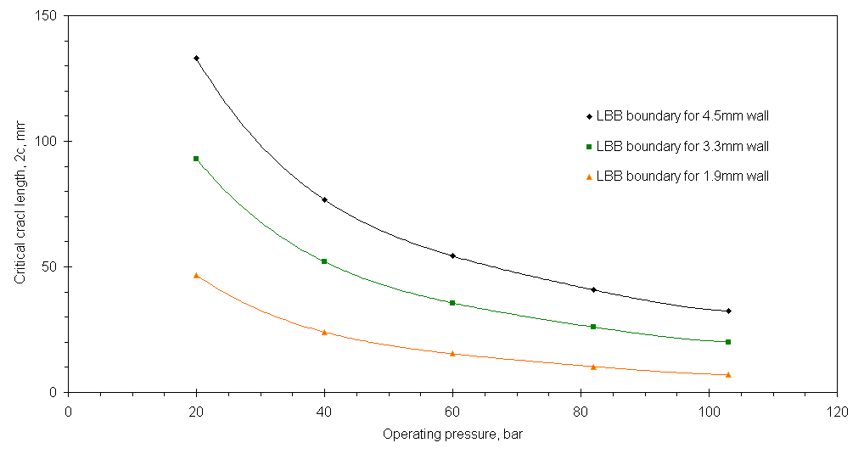

- To determine the relationship between critical crack size and operating pressure

- To establish safe exclusion zones

Approach:

- Fracture mechanics assessment, including leak-before-break analysis

- Steam release calculations

Findings:

- Following hydrostatic testing at ambient conditions (and the inspections undertaken) the maximum current defect size was established

- The failures can be explained solely on the basis of the tube pressure stress and predictions are consistent with the observed failure mechanism and final crack size

- Leak before break analysis provided relationship between operating pressure and critical crack size and hence the likelihood of each failure mode during operation

Results:

- Critical crack sizes determined as a function of operating pressure and wall thickness

- Safe operating pressures determined from observed crack sizes

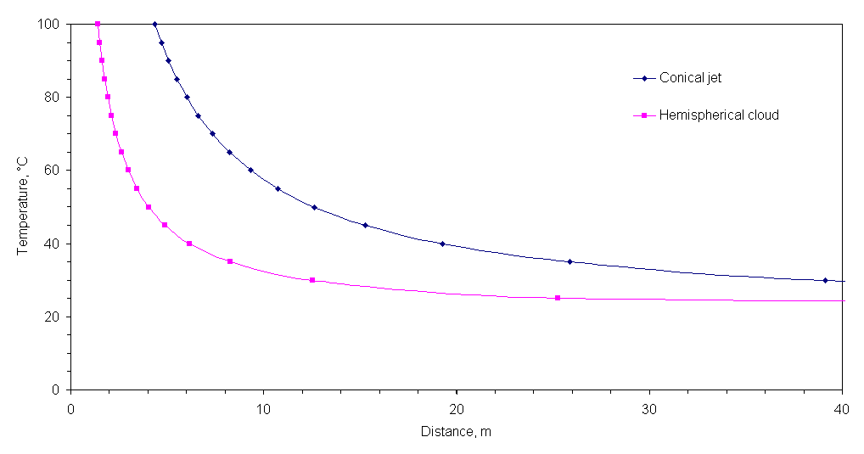

- Standard gas release calculations found to be inappropriate for steam

Safe exclusion zones determined on the basis of more accurate release formulae

Benefits:

- Explosive type failures can be eliminated by reduced pressure operation

- Unit brought back on-line during critical period

- Fast response by team leads to minimal downtime

- Insurers satisfied by comprehensive analysis undertaken