Item:

- Four coke drums, fabricated from C½Mo steel, one of which exhibited a through-wall crack, in excess of 1m length, at a circumferential weld

- Welds were observed to show considerable misalignment

Objective:

- To assess the life of the drums under the current operating regime

- To define appropriate inspection requirements to underwrite future operation

- To obtain appropriate materials data for this and future assessments

Approach:

- Finite element thermal and stress analysis, of as-built geometry

- Testing of samples removed during drum repair

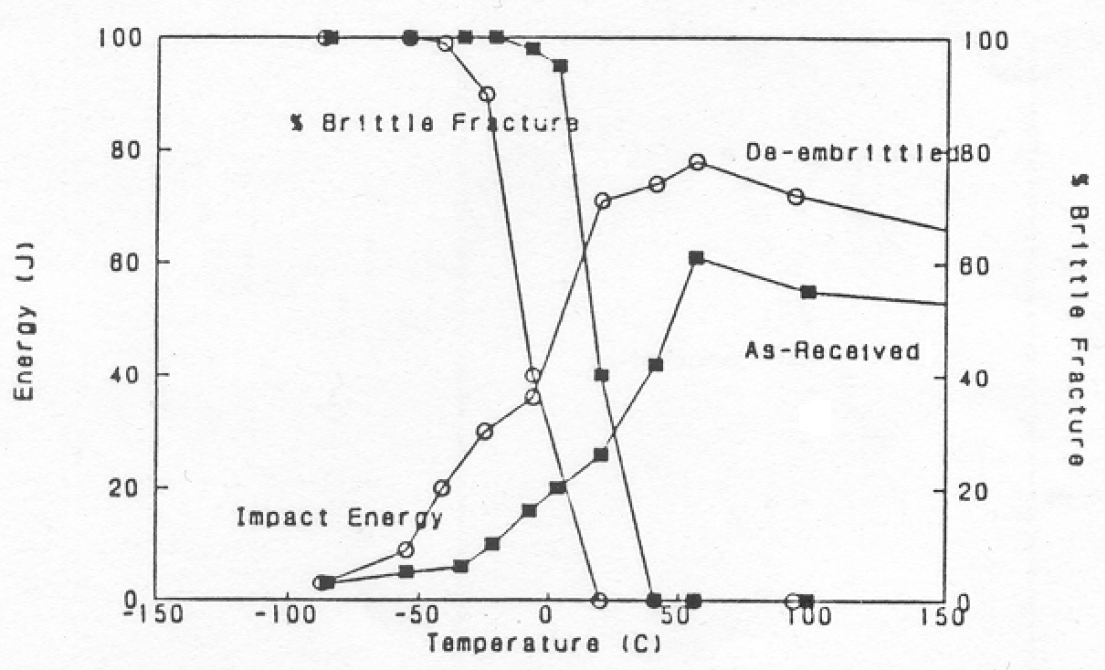

- Fracture toughness estimated from Charpy impact data using established correlations

- Significance of in-service embrittlement determined by testing de-embrittled material

- Fatigue crack growth rates measured using double edge notched specimens

- Probabilistic life assessment, covering fatigue crack growth to critical size of a defect population with the observed size distribution

Outcome:

- Failure times determined to be of the order of 500 cycles from crack detection

- Two-yearly inspections recommended, with removal or repair of all defects found

- Recommendation to measure actual metal temperatures during the operating cycle in order to refine the analysis

Publication:

Annis, V.A., Brear, J.M. and Cane, B.J.

“Integrity evaluation of cyclically operated process plant”

Proc Fourth Int Conf ‘Creep and Fracture of Engineering Materials and Structures’ Swansea, April 1990, Published Inst. Metals, London, pp 1073-1081