Plant:

- A 270 MW gas fired boiler, of once-through (Benson) type with 180,000h service.

- After 5 years base-load operation followed by 20 years of load following, the utility wishes to run in a two-shifting regime for 8 more years.

Objective:

A Phase 1 remaining life assessment of:

- all critical headers (22 types)

- some internal pipework (2 bends)

- some tubes (2 banks)

Basis of assessment:

- Current condition (calculated life consumed)

- operating conditions to date - Remaining life

- proposed change from load following to two shifting - Mechanisms

- low temperature headers - fatigue only

- high temperature components - creep and fatigue

- tubes - creep, fireside corrosion, steamside corrosion - Input data

- actual and expected operating conditions

- design materials data and dimensions - Code based stress analysis (TRD)

- all key locations

Operational events considered:

- Starts

- Cold to 40 MW

- Cold to full load

- Warm to full load

- Hot to full load

- Load changes

- 40 – 270

- 270 – 40 MW

- 80 – 160 MW

- 40 – 270 – 130 – 270 – 40 MW (full 24h cycle)

- Unit trip

Excursions and instabilities:

Known in advance:

- Economiser

- cold-water pull-through from de-aerator on run-up - Evaporator, level maintaining vessel, cyclones

- feedwater choke on transition to once-through operation

Discovered during the assessment:

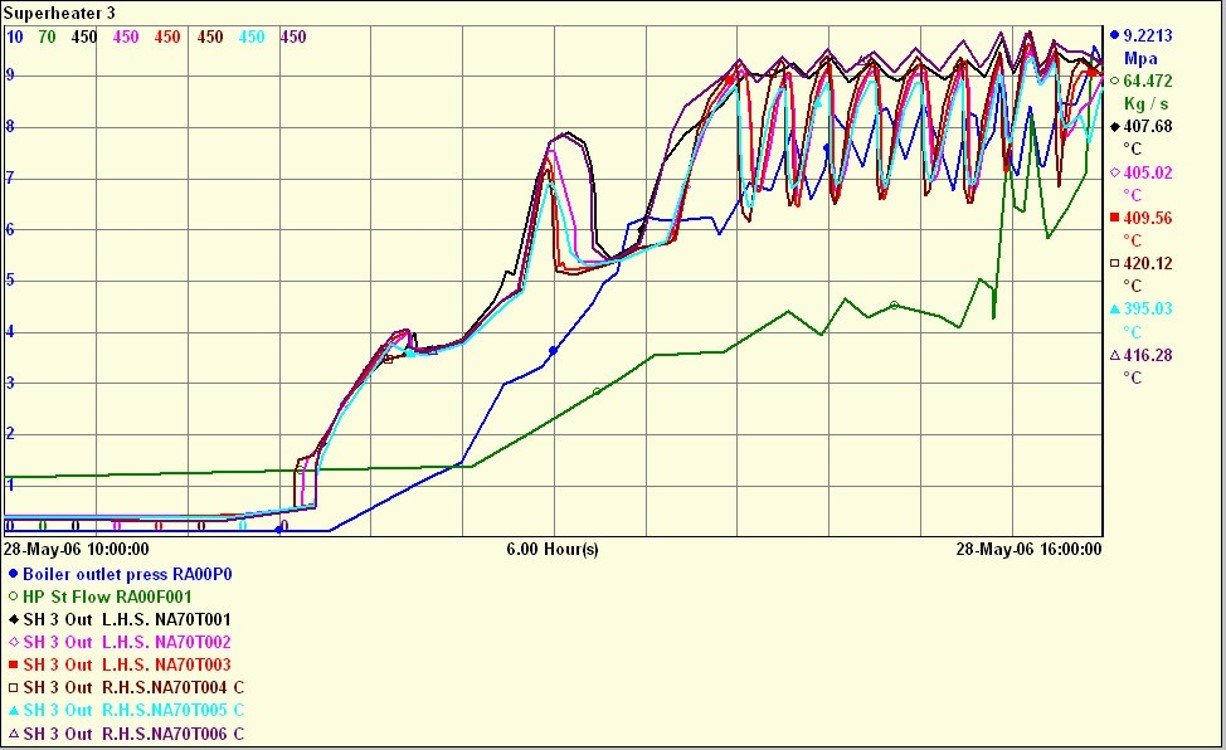

- Superheaters 3 and 4, Reheater 2

- Attemporator instability - Reheater 1

- Bypass instability

Results - fatigue:

- Two components were calculated to be fatigue critical at the assessment time

- If instabilities have their maximum effect, then a further component was also calculated to be fatigue critical at the assessment time

- Three components were calculated to become fatigue critical during the next 8 years

- If instabilities have their maximum effect, then a further component was also calculated to become fatigue critical during the next 8 years

Results - creep and fatigue combined:

- Two components were calculated to be creep strain critical at the assessment time

- One of these was also critical with regard to calculated total damage at the assessment time and the calculated total damage was predicted to exceed 1 within the next 8 years

- The other was predicted to become critical with respect to calculated total damage during the next 8 years

Recommendations:

- Further data, necessary to refine the assessment for those components which were predicted to become critical within the next 8 years, were identified

- Future inspection plans were formulated

- Scope and timing

- Techniques - Potential replacements were identified