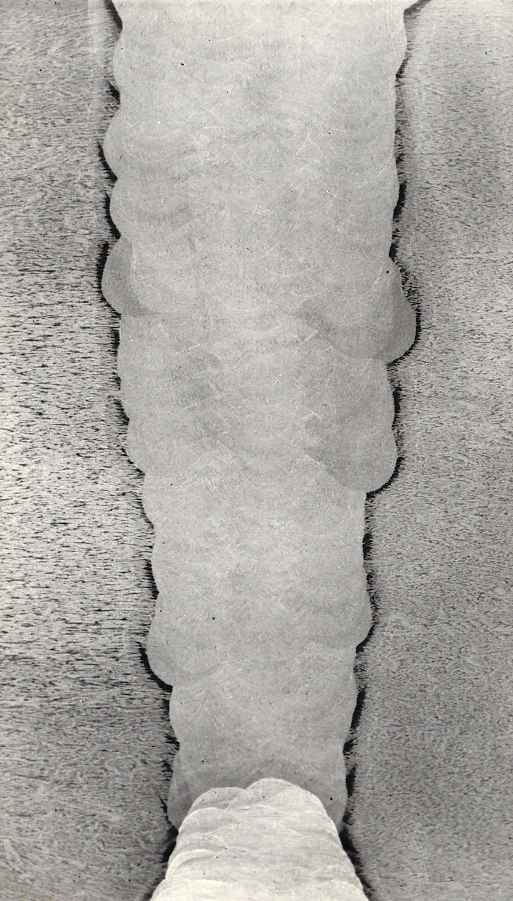

PWR pressure vessel weld[/caption]On the decision to move towards a PWR programme in the UK, it was realised from previous experience that structural and cladding welds in the pressure vessels could be subject to various forms of embrittlement. The nozzle-ring and belt-line areas were seen to be particularly critical. A joint working-group involving the utility, the construction consortium, government institutions and the statutory body was established to address this.

A significant task was to identify achievable residual-element limits for base metal and weld consumables, so as to reduce the susceptibility to stress-relief, temper and irradiation embrittlement to tolerable levels. The work involved extensive mechanical testing of controlled-purity alloys and commercial steels from a range of manufacturers, welded to various procedures. Detailed metallography – including Auger analysis – was performed on the test-pieces. Mechanistic models of the different degradation processes were developed, allowing quantification of the effects of each impurity element on each embrittling mechanism. Thence the kinetics of in-service embrittlement could be determined.

The work resulted in an agreed residual element specification for the selected steels, recommendations as to construction and fabrication routes, and a proposed monitoring programme using surveillance specimens.

Publications based on this work include:

Brear, J.M.

“Approaches to predicting the kinetics of grain boundary segregation in ferritic steels”

Inst Metals Conf `Intergranular Failure Mechanisms in Steel’, London, March 1988

Brear, J.M. and King, B.L.,

“An assessment of the embrittling effects of certain residual elements in two nuclear pressure vessel steels (A533B, A508)”,

Conf ‘Residuals, Additives and Materials Properties’, Royal Society, May 1978, Phil Trans R Soc, London, A295, 1980, p.291

Brear, J.M. and King, B.L.

“Reheat cracking in nuclear reactor pressure vessel steels”

Int J Pressure Vessels and Piping, Vol 7, 1979, pp.339-40

Brear, J.M. and King, B.L.

“Stress relief embrittlement in Mn-Mo-Ni pressure vessel steels”

Inst Metallurgists, Spring Residential Conf ‘Grain Boundaries’, Jersey, 1976, pp.C13-18